Maintenance

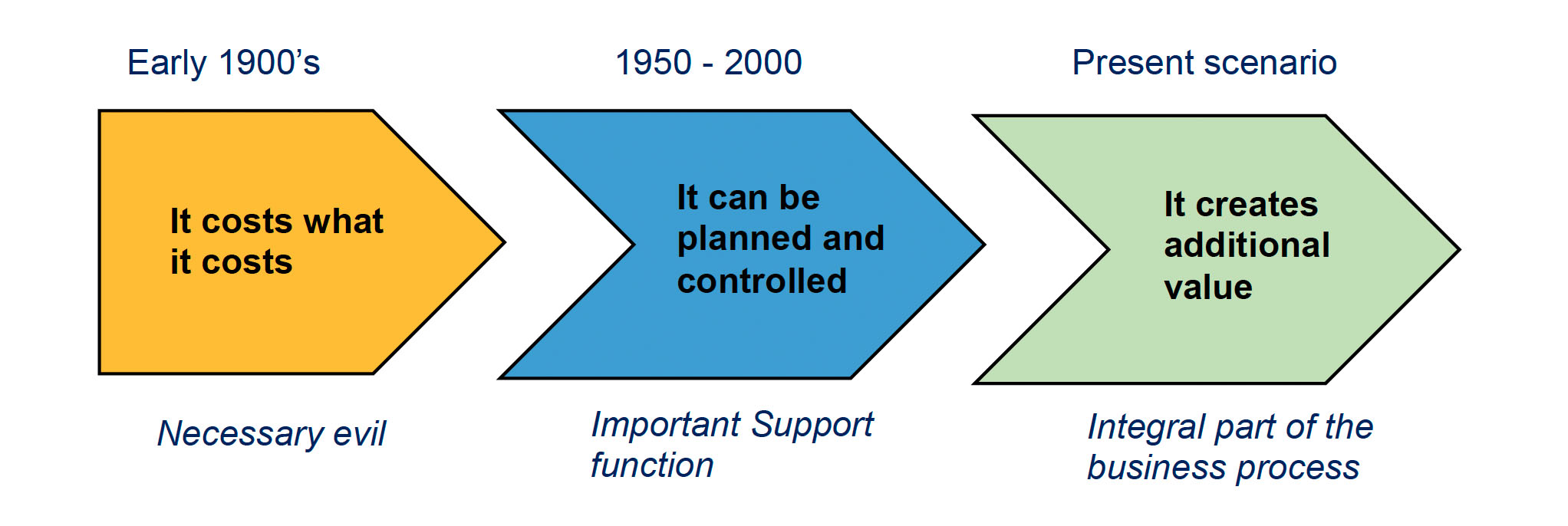

The maintenance process, as a supportive function to keep the production processes operational has changed in value over the past century.

In the early 1900’s there was no alternative for avoiding failure, and maintenance was considered a necessary evil. In the years 1950‐2000 maintenance could be planned and controlled, with techniques like preventive maintenance and condition monitoring. Nowadays maintenance creates additional value as an integral part of the business process (Parida and Kumar 2006).

The BETA Performance Improving Methodology had been developed as a problem structuring method in which the end‐users and other key departments, are involved throughout the process of model building.

Be careful not to get maintenance activities confused with maintenance improvement. Merely doing something differently or implementing a new maintenance program does not necessarily mean that maintenance will improve.

Improvements will come with the incorporation to the Maintenance Program of:

- New preventive maintenance (PM) procedures developed by the end users and adapted to their needs.

- Operational areas, that became direct involved in the Maintenance Process, (as an example, operational personnel performing basic equipment lubrication as part of Total Productive Maintenance (TPM) development).

- The purchase process, by an active participation in the Corrective Maintenance model.

- The financial process to evaluate cost reduction and give more meaning to the Preventive or Corrective Maintenance Program.

- Quality and Work Teams to evaluate the specific root causes of the barriers that avoids this integration in that Particular Organization and re-focus on each specific business case to design the proper Maintenance System or improve the existing one.

BETA Maintenance Program electronically supported by the application software i-Activos will provide an easy and strong tool to improve Maintenance performance within your Organization.